Chain Info

This is a section all about our other bread and butter, Chain.

Chain has many purposes and is the predecessor to wire rope. It is the same as wire rope in that under compression it will curve and under tension it will become linear, rigid and load bearing. This makes it reliable for lifting and rigging applications. It has its advantages and disadvantages over wire rope when making assemblies and applying them to rigging applications.

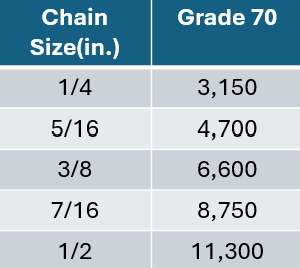

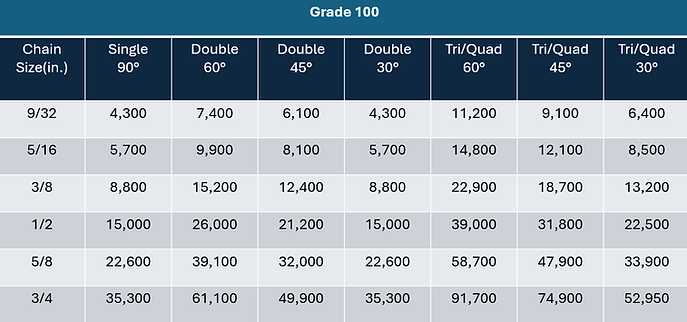

Making chain assemblies is like working with Legos, we take an order, convert it into a code that conveys the type and length of the assembly, and make the assembly out of either grade 70 or grade 100 chain, depending on what working load or chain visibility you need.

We make assemblies out of import or domestic chain or wire rope, to customer's preference and specification.

Grade of chain is determined by the NACM (National Association of Chain Manufacturers) & ASTM (American Society for Test Materials). The higher the grade, the higher the working load limit. WLL (Working Load Limit) is the measure of the maximum working load that should be applied to an undamaged straight length of chain.

Overhead lifting is the concept that there are much less tolerances afforded to any company lifting and rigging above the heads of people. This also extends to anything that will be used to move people. The safe working load may be temporarily lowered on behalf of the fact that people are not cargo. Always remember to read local, state and federal laws and building codes for all thing pertaining to overhead lifting. Also, always refer to applicable codes, standards and regulations for inspection requirements and removal criteria.

Grade 100 chain sling WLL(s)

The other type of chain we sell is grade 70 chain, which is not certified for overhead lifting but is well suited for things such as pulling, binding and towing applications.